Engineering Aspects of the C2 & C3 Corvette

1968 – 1982

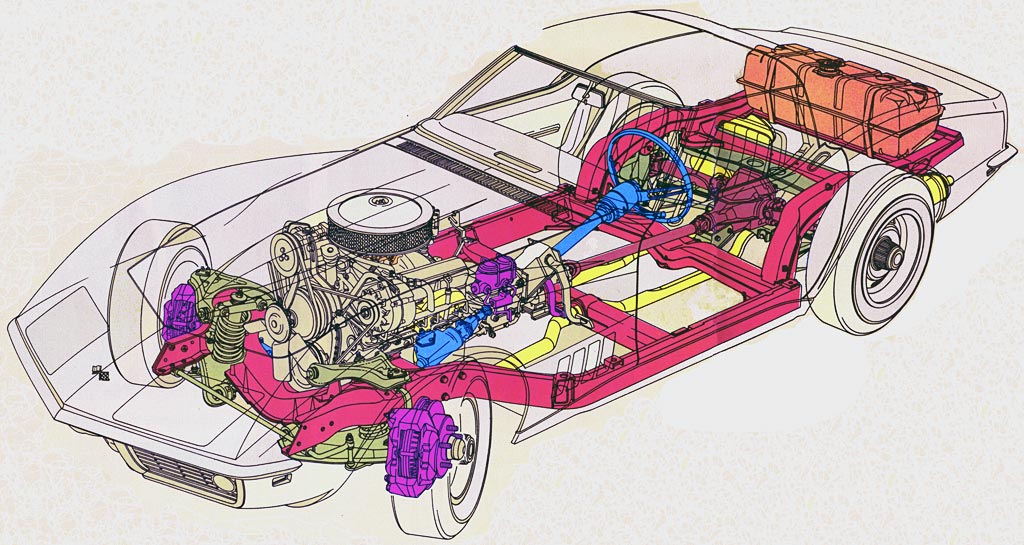

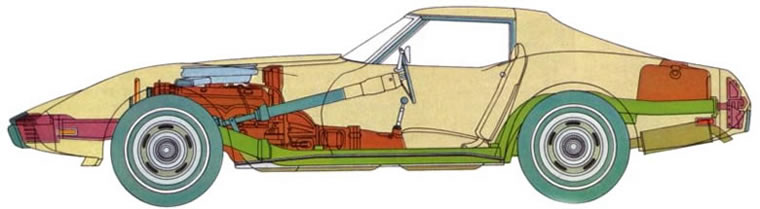

The C2 and C3 generations of Corvettes both use the same underlying chassis. This advanced chassis for the time, was designed by Zora Arkus Duntov, Chief Engineer for the Corvette division of GM.

Engine Placement

Muscle cars of this era generally positioned the engine over the front wheels of the car severely hampering handling. The Corvette moved the engine back towards the middle of the car and down, more like a mid-engine car, this took weight off of the steering and front wheels, and also lowered the cars centre of gravity, thus greatly improving handling.

IRS

Since the C2 introduction is 1963, corvette has utilized Independent Rear Suspension, although IRS is common now, it was very rare in the 60s and 70s, and even the 80s. The biggest advantage the Corvettes IRS has is its ability to keep the rear tires in better contact with the road . This fact significantly improved the cars ability to corner as well as give a better ride than is possible with a “live” rear axle car like the C1 it replaced. The independence of wheel motion and straight tracking as it moves up and down in response to bumps allows it to adapt to irregular surfaces. The unique implementation of IRS on the C2 and C3 Corvettes uses small shafts (called half shafts) on each side of the differential which is tied on each side with universal joints (just like a drive shaft). The outer end is connected to the wheel hub which is mounted on a trailing arm. The inner end is connected to the differential which is itself bolted to the frame. The fact that the heavy differential is not part of the unsprung weight greatly improves handling.

Since the C2 introduction is 1963, corvette has utilized Independent Rear Suspension, although IRS is common now, it was very rare in the 60s and 70s, and even the 80s. The biggest advantage the Corvettes IRS has is its ability to keep the rear tires in better contact with the road . This fact significantly improved the cars ability to corner as well as give a better ride than is possible with a “live” rear axle car like the C1 it replaced. The independence of wheel motion and straight tracking as it moves up and down in response to bumps allows it to adapt to irregular surfaces. The unique implementation of IRS on the C2 and C3 Corvettes uses small shafts (called half shafts) on each side of the differential which is tied on each side with universal joints (just like a drive shaft). The outer end is connected to the wheel hub which is mounted on a trailing arm. The inner end is connected to the differential which is itself bolted to the frame. The fact that the heavy differential is not part of the unsprung weight greatly improves handling.

It wasn’t until 1992 – Twenty nine years after the introduction of the 1963 Corvette that a car with an IRS designed by Chrysler (the 1992 Viper) was available to the public.

Transverse Rear Leaf Spring

Since 1963, Corvettes have used Transverse Leaf Springs in the Rear and starting in 1981 they were changed from Steel to Composite. Many people are critical of the rear leaf spring equating it with old technology adding that coil springs are better. Nothing could be further from the truth.

Advantages

▪ Less unsprung weight. Coil springs contribute to unsprung weight; the less there is, the more quickly the wheel can respond at a given spring rate.

▪ Less weight. The C4 Corvette’s composite front leaf weighed 1/3 as much as the pair of conventional coil springs it would replace. Volvo reported that the single composite leaf spring used in the rear suspension of the 960 Wagon had the same mass as just one of the two springs it replaced.

▪ Weight is positioned lower. Coil springs and the associated chassis hard mounts raise the center of mass of the car, which is not a good thing.

▪ Superior wear characteristics. The Corvette’s composite leaf springs last longer than coils, though in a car as light as the Corvette, the difference is not especially significant. No composite Corvette leaf has ever been replaced due to fatigue failure, though steel leafs from 1963 to 1983 have been. The spring rate on a composite spring never changes like does with a steel spring. As of 1980, the composite spring was an option on the C3.

▪ As used on the Corvette, ride height can be adjusted by changing the length of the end links connecting the leaf to the suspension arms. This allows small changes in ride height with minimal effects on the spring rate.

▪ Also as used on the C4 front suspension, C5, and C6 Corvettes, the leaf spring acts as an anti-roll bar, allowing for smaller and lighter bars than if the car were equipped with coil springs. As implemented on the C3 and C4 rear suspensions with a rigid central mount, the anti-roll effect does not occur.

▪ Packaging. As used on the C5 and later Corvettes the use of OEM coil over damper springs would have forced the chassis engineers to either vertically raise the shock towers or move them inward. In the rear this would have reduced trunk space. In the front this would have interfered with engine packaging. The use of the leaf spring allowed the spring to be placed out of the way under the chassis and while keeping the diameter of the shock absorber assembly to that of just the damper rather than damper and spring.

Front Hinged Hood

The front hinged hood found on the Corvette is a safer method as wind cannot open an unlatched hood at high speeds.

Disc Brakes

Since 1965 disc brakes were standard on the Corvette. The Delco designed system had 4 pistons per caliper giving outstanding braking ability.